Conventional technologies are those that have a successful track record in mine site cleanup and site remediation. At Anderson, we have implemented many of these technologies and methods on over 100 different remediation projects across the Western United States.

Conventional technologies are those that have a successful track record in mine site cleanup and site remediation. At Anderson, we have implemented many of these technologies and methods on over 100 different remediation projects across the Western United States.

Conventional technologies are those that have a successful track record in mine site cleanup and site remediation. At Anderson, we have implemented many of these technologies and methods on over 100 different remediation projects across the Western United States.

Landfill Disposal

Landfills are waste management units, usually dug into the ground, but include above ground units which are not exposed on the sides (i.e., not freestanding waste material heaps), that take waste material for long-term placement and disposal. Although landfilling is a conventional disposal technology, it has had its share of new innovative developments. Landfills may be lined to hold leachate, drained with a leachate collection system, and capped. The cost of landfills can range from medium to high at mining and mineral processing sites depending on the site remediation circumstances that affect the design, such as low permeableness, low permeability liner, leachate collection, and leachate treatment. The O&M costs of leachate treatment or cap upkeep can be considerable. The efficiency of the landfill is dependent on the design. A landfill that can insulate the waste is effective. Should the cap or liner be broken, however, the usefulness is significantly reduced. Landfills, on-site, should be designed to meet site remediation goals and address relevant regulatory criteria.

Cutoff Walls for Groundwater Protection

Cutoff walls are structures used to restrict the movement of groundwater from either exiting a location, in the case of contaminated groundwater, or penetrating a contaminated area, in the case of clean groundwater. Types of cutoff walls often found in site remediation projects consist of slurry walls, cement walls, and sheet piling.

- Slurry Walls – Cutoff walls are structures used to restrict the movement of groundwater from either exiting a location, in the case of contaminated groundwater, or penetrating a contaminated area, in the case of clean groundwater. Types of cutoff walls consist of slurry walls, cement walls, and sheet piling.

- Cement Walls – Cement walls are comparable to the slurry walls, other than instead of a low permeability clay-type slurry, a cement-based slurry is used. Construction may be by trench and fill much like the slurry wall construction. At the same time, construction may utilize a more substantial excavation for which forms are built to pour a concrete wall, after which the excavated area around the wall is backfilled. The backfill may be with a high permeability material employed to capture and channel the groundwater flow (e.g., for recovery if contaminated, or to prevent its contamination). The cost of the cement walls is higher than the slurry walls, mainly if the wall is formed in place, with a cost range of medium to high. This higher cost may increase performance.

- Sheet piling – Sheet piling is a tech that is frequently utilized to install a cutoff wall. Sheet piling has been used in the past to channel groundwater to a treatment cell for treatment and is frequently used as a short-term cutoff wall during the remediation stage. The cost of the sheet piling is in the medium to high range, with the high range utilizing a better process to seal the joints in between the sheets. The efficiency of sheet piling is comparable to the slurry wall, but there is a higher potential of the wall to have leaks at the joints.

Pumping Groundwater for Remediation Treatment

In site remediation, the pump-and-treat process for treating groundwater contamination is a combination of an extraction technology (pumping) and a subsequent treatment system. Treatment options are discussed here. The pump-and-treat technologies have been the favored means of remediating contaminated groundwater. The cost of the pumping portion can range from medium to high, including, but not limited to, the number and spacing of wells, the volume to be pumped, and the depth to groundwater. The long-term efficiency of this procedure is limited for select contaminants, especially certain metals, in select soil types. Thought has to be given to such facets as desorption rates and chemical properties of the contaminants themselves.

Capping for Soil Pollution in Site Remediation

Capping is commonly utilized in site remediation to cover a contaminated area or waste unit to restrict precipitation from infiltrating the location, to restrict contaminated material from being transported out of the area, and to restrict human or animal interaction with the contaminated materials. An instance of preventing releases is the planting of vegetation on tailings to avoid fugitive dust from blowing off and being transported downwind. A case of preventing human contact is the removing and replacing of a designated depth of soil in a residential location, which has been used to protect the occupants from the contaminated subsoils.

Capping may include surface armoring, soil/clay cover, soil enhancement to encourage growth, geosynthetic or asphaltic cover system, polymetric/chemical surface sealers, revegetation, concrete, and synthetic covers. The expense of caps can range from low (e.g., planting grasses) to high (e.g., synthetic caps) dependent on the cap selected. The cap may or may not be successful in achieving the different performance objectives, for example; a cap designed to minimize erosion may not be a practical cap to minimize infiltration and vice versa.

Detention/Sedimentation for Soil Cleanup

Detention/sedimentation controls are utilized to control erosion and sediment-laden runoff. “Treatment” usually consists of essentially slowing the water flow and decreasing the corresponding turbulence to let solids settle out. Settling may be acceptable at natural rates; in different situations, flocculants may be incorporated to help improve the settling rate. The settled sediments may be removed and disposed of; if the sediment is contaminated, then treatment could be necessary. The cost of detention and sedimentation is generally in the range of low to medium, depending on the O&M costs to do away with the settled solids. The detention/sedimentation basins can be practical if they can be designed to allow the proper amount of settling time; however, in some cases, the solids settle at a prolonged rate, and a percentage of the solids leave the settling basin.

Settling Basins

Settling basins could be utilized to contain surface waters so that contaminated sediments suspended in the water can easily be treated, settled, and handled accordingly. Dissolved contaminants and acid waters may be controlled as well to allow for treatment or natural degradation (e.g., contained cyanide degrade naturally). As the impoundment fills with the solids that have settled out, solids must be extracted and disposed of for the impoundment to continue functioning correctly. The cost of operating settling basins is in the low to medium range, dependant on the construction of the impoundment and dam. For example, a lined impoundment cost more than an unlined impoundment. Expertly designed settling basins can be successful in the removal of suspended solids from surface waters.

Conventional technologies are those that have a successful track record in mine site cleanup and site remediation. At Anderson, we have implemented many of these technologies and methods on over 100 different remediation projects across the Western United States.

In performing environmental reclamation and site remediation projects, there are three major categories: conventional, innovative/emerging, and institutional controls. Within conventional, there are three subcategories: Treatment technologies, Collection, Diversion, and Containment Technologies (this article), Reuse, Recycle, Reclaim.

The use of each technology is dependent on the requirements of the project and the nature of the contaminants. Collection, Diversion, and Containment are most often used at sites where treatment cannot control the contaminants to an acceptable level or the long-term operations cost justifies their use.Table Of Contents

- Landfill Disposal

- Cutoff Walls for Groundwater Protection

- Pumping Groundwater for Remediation Treatment

- Capping for Soil Pollution in Site Remediation

- Detention/Sedimentation for Soil Cleanup

- Settling Basins

- Interceptor Trenches

- Erosion Controls

- Diversions

- Stream Channel Erosion Controls

Landfill Disposal

Landfills are waste management units, usually dug into the ground, but include above ground units which are not exposed on the sides (i.e., not freestanding waste material heaps), that take waste material for long-term placement and disposal. Although landfilling is a conventional disposal technology, it has had its share of new innovative developments. Landfills may be lined to hold leachate, drained with a leachate collection system, and capped. The cost of landfills can range from medium to high at mining and mineral processing sites depending on the site remediation circumstances that affect the design, such as low permeableness, low permeability liner, leachate collection, and leachate treatment. The O&M costs of leachate treatment or cap upkeep can be considerable. The efficiency of the landfill is dependent on the design. A landfill that can insulate the waste is effective. Should the cap or liner be broken, however, the usefulness is significantly reduced. Landfills, on-site, should be designed to meet site remediation goals and address relevant regulatory criteria.https://www.youtube.com/embed/QYBvntdO6YM?feature=oembed&enablejsapi=1&origin=https://www.andersoneng.com/

Cutoff Walls for Groundwater Protection

Cutoff walls are structures used to restrict the movement of groundwater from either exiting a location, in the case of contaminated groundwater, or penetrating a contaminated area, in the case of clean groundwater. Types of cutoff walls often found in site remediation projects consist of slurry walls, cement walls, and sheet piling.

- Slurry Walls – Cutoff walls are structures used to restrict the movement of groundwater from either exiting a location, in the case of contaminated groundwater, or penetrating a contaminated area, in the case of clean groundwater. Types of cutoff walls consist of slurry walls, cement walls, and sheet piling.

- Cement Walls – Cement walls are comparable to the slurry walls, other than instead of a low permeability clay-type slurry, a cement-based slurry is used. Construction may be by trench and fill much like the slurry wall construction. At the same time, construction may utilize a more substantial excavation for which forms are built to pour a concrete wall, after which the excavated area around the wall is backfilled. The backfill may be with a high permeability material employed to capture and channel the groundwater flow (e.g., for recovery if contaminated, or to prevent its contamination). The cost of the cement walls is higher than the slurry walls, mainly if the wall is formed in place, with a cost range of medium to high. This higher cost may increase performance.

- Sheet piling – Sheet piling is a tech that is frequently utilized to install a cutoff wall. Sheet piling has been used in the past to channel groundwater to a treatment cell for treatment and is frequently used as a short-term cutoff wall during the remediation stage. The cost of the sheet piling is in the medium to high range, with the high range utilizing a better process to seal the joints in between the sheets. The efficiency of sheet piling is comparable to the slurry wall, but there is a higher potential of the wall to have leaks at the joints.

Pumping Groundwater for Remediation Treatment

In site remediation, the pump-and-treat process for treating groundwater contamination is a combination of an extraction technology (pumping) and a subsequent treatment system. Treatment options are discussed here. The pump-and-treat technologies have been the favored means of remediating contaminated groundwater. The cost of the pumping portion can range from medium to high, including, but not limited to, the number and spacing of wells, the volume to be pumped, and the depth to groundwater. The long-term efficiency of this procedure is limited for select contaminants, especially certain metals, in select soil types. Thought has to be given to such facets as desorption rates and chemical properties of the contaminants themselves.https://www.youtube.com/embed/Y6zFgUHDT-Y?feature=oembed&enablejsapi=1&origin=https://www.andersoneng.com/

Capping for Soil Pollution in Site Remediation

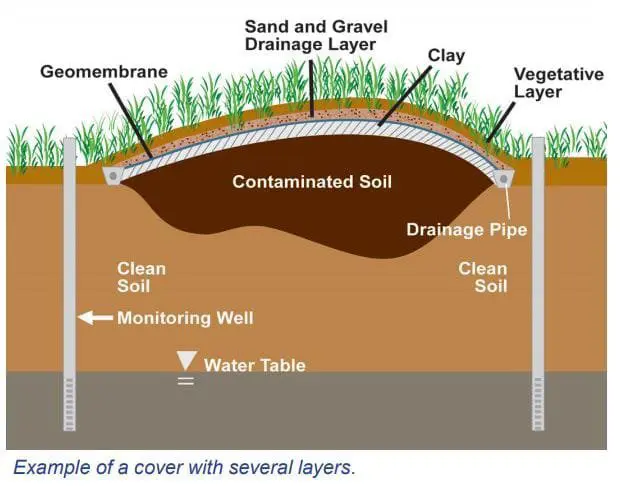

Capping is commonly utilized in site remediation to cover a contaminated area or waste unit to restrict precipitation from infiltrating the location, to restrict contaminated material from being transported out of the area, and to restrict human or animal interaction with the contaminated materials. An instance of preventing releases is the planting of vegetation on tailings to avoid fugitive dust from blowing off and being transported downwind. A case of preventing human contact is the removing and replacing of a designated depth of soil in a residential location, which has been used to protect the occupants from the contaminated subsoils.

Capping may include surface armoring, soil/clay cover, soil enhancement to encourage growth, geosynthetic or asphaltic cover system, polymetric/chemical surface sealers, revegetation, concrete, and synthetic covers. The expense of caps can range from low (e.g., planting grasses) to high (e.g., synthetic caps) dependant on the cap selected. The cap may or may not be successful in achieving the different performance objectives, for example; a cap designed to minimize erosion may not be a practical cap to minimize infiltration and vice versa.

Detention/Sedimentation for Soil Cleanup

Detention/sedimentation controls are utilized to control erosion and sediment-laden runoff. “Treatment” usually consists of essentially slowing the water flow and decreasing the corresponding turbulence to let solids settle out. Settling may be acceptable at natural rates; in different situations, flocculants may be incorporated to help improve the settling rate. The settled sediments may be removed and disposed of; if the sediment is contaminated, then treatment could be necessary. The cost of detention and sedimentation is generally in the range of low to medium, depending on the O&M costs to do away with the settled solids. The detention/sedimentation basins can be practical if they can be designed to allow the proper amount of settling time; however, in some cases, the solids settle at a prolonged rate, and a percentage of the solids leave the settling basin.

Settling Basins

Settling basins could be utilized to contain surface waters so that contaminated sediments suspended in the water can easily be treated, settled, and handled accordingly. Dissolved contaminants and acid waters may be controlled as well to allow for treatment or natural degradation (e.g., contained cyanide degrade naturally). As the impoundment fills with the solids that have settled out, solids must be extracted and disposed of for the impoundment to continue functioning correctly. The cost of operating settling basins is in the low to medium range, dependant on the construction of the impoundment and dam. For example, a lined impoundment cost more than an unlined impoundment. Expertly designed settling basins can be successful in the removal of suspended solids from surface waters.

Interceptor Trenches

Interceptor trenches are trenches that have been loaded with a

permeable material, like gravel, which can receive the groundwater flow and reroute it for either in-situ or ex-situ treatment. Interceptor trenches are frequently used to collect and treat groundwater and restrict it from leaving a containment area, e.g., a landfill. The initial cost of interceptor trenches is low to moderate, depending on the accessibility of materials. However, the O&M cost can be substantial if the liquid in the trench precipitates material that will plug the trench, reducing the permeability and necessitating the permeable material to be cleaned or replaced. Interceptor trenches are good at capturing groundwater flow if the permeability of the media in the trench is higher than the native material.

Erosion Controls

Erosion controls are those engineering controls utilized to remove or minimize the erosion of contaminated soils by either air or precipitation (i.e., stormwater or snowmelt). Erosion controls consist of:

- Cappings or covers, especially in the form of revegetation, polymer/chemical surface sealers, armoring, and soil enhancements. The caps or covers for erosion control, frequently, are lower than the costs of caps to restrict infiltration. The cost range of the erosion control caps is low to medium. The O&M costs of the cap could be considerable, especially if the cap or cover can be easily impaired. For example, if revegetation is selected, then the O&M costs will consist of revegetating spots whenever the vegetation does not grow or is compromised by factors which could include natural circumstances such as drought or pest intrusion. The usefulness of the caps or covers to minimize erosion is dependent on site conditions; however, the caps or covers should usually prevent the erosion of soils by either water or air.

- Windbreaks are applied to minimize the erosion of soils and dust by the wind and can entail planting of trees and other vegetation to lessen the wind velocity, and/or the construction of fences. The cost of windbreaks is generally in the low to medium range. The performance of windbreaks is dependent on the prevailing wind. In general, windbreaks are not as efficient at eliminating airborne dust as the caps or covers.

- Diversions (as discussed below) are employed to manage surface water around areas that have a high possibility of erosion. An instance of this would be the construction of a diversion ditch to catch runoff, which reduces the flow from reaching a steep slope, in which it could cause erosion.

Diversions

Diversions are engineering controls that are utilized to divert groundwater or surface water from infiltrating waste units or areas of contamination, thereby blocking the media from becoming contaminated and pollutants from leaching and migrating. Two forms of

diversions are run-on controls and capping:

- Run-on controls restrict surface water from entering waste units or areas of contamination and becoming contaminated. For example, surface waters may be redirected to avoid contact with stockpiled waste rock. This would restrict the water from becoming acidified. Examples of run-on controls could consist of retaining walls, gabion dams, check dams (both permanent and temporary), and diversion ditches. The costs of run-on controls are low to medium dependant on the technique used for the diversion. The use of run-on controls to move surface water away from areas of contamination is useful in decreasing the amount of water that needs treatment.

- Capping is the placing of synthetic liners or imperviable earthen materials (typically clay) to restrict precipitation from infiltrating waste materials or significantly contaminated areas and leaching contaminants into the groundwater. This allows water to be captured and redirected someplace else.

Stream Channel Erosion Controls

Stream channel erosion controls are made use of to decrease the mobilization and transport of contaminated sediments by streams inside of the site. At some mining and mineral handling sites, historical transportation of contaminated sediment into the stream has happened. Numerous sites have locations wherein these sediments have become deposited on stream shores and beds. Stream channel erosion controls can be used to lower the remobilization and transport of these sediments, usually in intervals of higher flows. Solutions to control stream channel erosion commonly entail both erosion controls and diversions such as channelization or lining channels, diversion dams and channels (construction of diversion dams and or channels to decrease flow to contaminated locations and groundwater recharge areas, to decrease water velocity, trap sediment and divert clean water), riprap, and gabions. The cost of these controls can vary from low (e.g., revegetation of stream banks) to high (e.g., diversion to an engineered channel) dependant on the site circumstances. Some of the techniques may be short-term until other remediations are completed. The O&M cost to the erosion controls could be considerable, particularly with destruction from flood events.